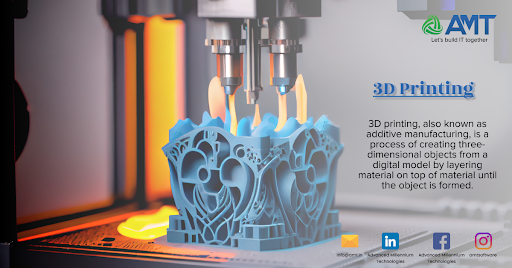

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects from a digital model by layering material on top of material until the object is formed. This technology has gained significant popularity and utility in various industries, including manufacturing, healthcare, aerospace, automotive, and more. Here are some key aspects of 3D printing:

- How it Works: 3D printing works by taking a 3D computer-aided design (CAD) model and slicing it into thin horizontal cross-sections or layers. The 3D printer then builds the object layer by layer, often using a range of materials such as plastics, metals, ceramics, or even organic compounds. Some common 3D printing methods include Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), and more.

- Materials: 3D printers can use a variety of materials depending on the type of printer and the intended application. Common materials include plastics like PLA and ABS, metals like aluminum and titanium, resins, ceramics, and even food-grade materials for culinary applications.

- Applications:

- Prototyping: 3D printing is widely used for rapid prototyping, allowing engineers and designers to quickly create physical models of their designs to test and iterate on them.

- Custom Manufacturing: It enables the production of highly customized and low-volume parts, such as dental implants, orthopedic implants, and personalized fashion items.

- Aerospace: Aircraft and spacecraft components, as well as prototypes, are often manufactured using 3D printing to reduce weight and improve efficiency.

- Medical: Custom prosthetics, dental devices, and even human organs and tissues are being developed using 3D printing technology.

- Art and Design: Artists and designers use 3D printing to create unique sculptures, jewelry, and other art forms.

- Education: 3D printing is used in educational settings to teach students about design, engineering, and manufacturing.

- Benefits:

- Customization: 3D printing allows for on-demand, highly customized production.

- Cost Efficiency: It can reduce waste by only using the material needed, making it more cost-effective for certain applications.

- Rapid Prototyping: Speeds up the product development cycle.

- Complex Geometries: 3D printing can create complex shapes and internal structures that are challenging or impossible with traditional manufacturing methods.

- Challenges:

- Material Limitations: Some materials used in 3D printing may not possess the same properties as traditionally manufactured materials, limiting their use in certain applications.

- Post-Processing: Depending on the printing method, objects may require post-processing to improve surface finish and structural integrity.

- Speed: 3D printing can be slower than traditional manufacturing methods, especially for large objects.

- Future Potential: 3D printing continues to evolve, with ongoing research and development into new materials, faster printing methods, and larger-scale applications. It has the potential to revolutionize various industries and supply chains by enabling local, on-demand production and reducing the need for extensive warehousing and transportation.

Above is a brief about 3D Printing. Watch this space for more updates on the latest trends in Technology.